이차전지 재료

Binder

CNP Solutions has differentiated conductive polymer synthesis and binder fabrication technology.

-

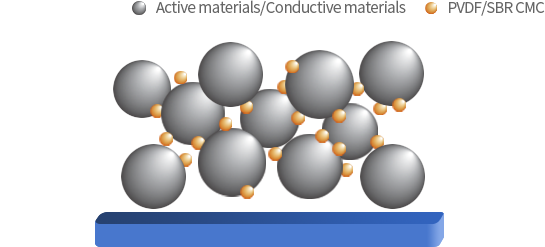

Conventional Binders

-

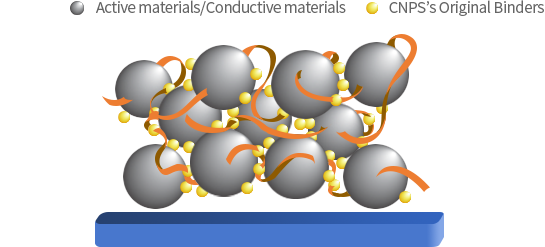

CNPS Binders

-

Conductivity

Using an electrically conductive polymers, electrode active material particles are designed to be connected through the polymeric binder even when the gap between the particles becomes longer larger.

The electrically conductive polymer binder provides excellent electrical connection between active material particles, resulting in an excellent electrical conduction through electrode layer. -

Binding property

Binder molecules are designed to reduce dimensional change during charging and discharging processes

-

Adhesive property

Excellent adhesion of electrodes to current collector

CNP SOLUTIONS Binders

CNP Solution developed 2 types of binder systems – for wet and dry systems– both improve adhesion between active materials,

ease of processing and increased electrical conductivity, enabling battery performance such as improved capacity retention and fast charging.

The dry-system without solvents surely contributes to the reduction of carbon footprint.

Binder for Wet-system

CNP Solutions’ wet binder system maximizes integration between active material particles,

hence improving adhesion and electrical conductivity.

- Conventional Binders

- CNPS’s Original Wet Binders

Binders for wet process Advantages

-

Excellent electrochemical

stability -

Excellent electrical

conductivity -

Excellent capacity

retention (Long-cycle Life)

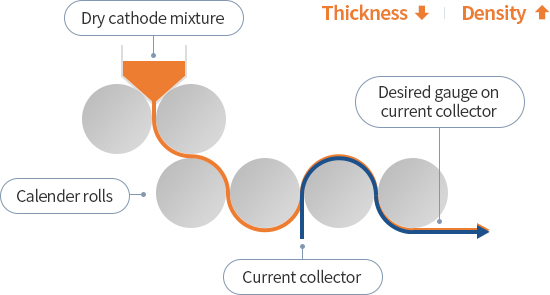

Binders for Dry-system

The CNP Solutions dry binder system is specially designed for lithium-ion battery dry-process and solid-state battery with excellent binding strength, adhesive force and capacity retention.

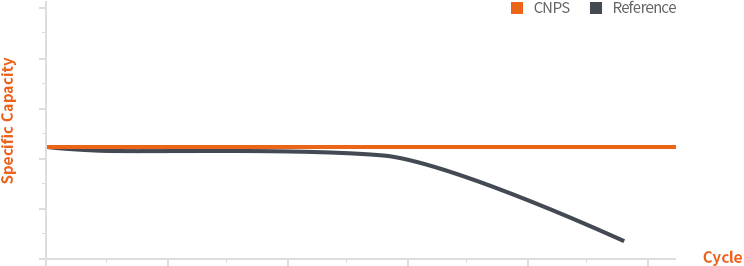

Binder Performance

Excellent capacity retention compared to reference

Binders for dry process Advantages

-

Achieve Zero-carbon

process -

Cost saving by

simplified manufacturing

process -

Improved processability

-

Improved binding performance